UC2 - Hydrogen Combustion for Propulsion

This use case targets the optimization of chevron nozzles to reduce noise emissions using a high-fidelity coupled flow-acoustics simulation approach.

Do you want to request support from EXCELLERAT staff or consulting on this Use Case?

*Registration is required to send inquiries.

Introduction

Future gas turbines will switch from fossil fuels to hydrogen. This technology is a key component of the decarbonization objectives of the EU which include the transition to alternative non-carbon fuel sources in the next 20 years. Fully integrated simulations of combustion systems using Hydrogen will be conducted with advanced high-performance computing on leading-edge HPC architectures to predict the operation and behaviour of these energy systems.

The Challenge

Switching to hydrogen fuels poses fundamental changes that require massive R&D. The schedule allowed for the design of these chambers is very tight, and companies will rely heavily on simulations to this end. Accounting for the differences in flame topology requires a massive adaptation in the design of combustion chambers, since hydrogen is a unique fuel, burning much faster, diffusing much faster, and exploding faster than all other conventional fuels raising safety concerns.

Building upon the modeling collaborations for H2 combustion (ERC SIROCCO, CoE COEC) in EXCELLERAT2 the automation of the user workflow for H2 simulation on EUROHPC – JU computing infrastructures.

Aim

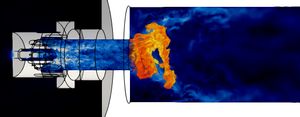

The use case aims to showcase the automatic workflow capabilities using static mesh refinement on EUROHPC infrastructures to improve time to solution and user accessibility for H2 combustion studies on the next generation of supercomputers using accelerators.

Development

UC2 builds upon the experience of EXCELLERAT phase 1 and focuses on the extension and portability of the lemming's workflow manager to allow for automated simulation of combustion large eddy simulation setups. For this, optimal components to handle the execution graph, simulation convergence checkers, mesh adaptation and top-of-the-line solvers on high-end hardware are required. From simple toy cases to experimental setups to a final industrial application will be progressively tackled throughout the 4 years of the project.

Building upon state-of-the-art modelling for H2 combustion, exascale mesh adaptation and solver acceleration on GPUs are major topics to be handled.

Benefits

The automation and optimisation of the hydrogen combustion workflow will allow to study and optimise ever more complex designs to aid the transfer from hydrocarbon to hydrogen combustion process in the aerospace industry. Highly resolved simulations using automated mesh refinement will improve by a least one order of magnitude the user time required for these studies and improve reproducibility and traceability of simulations in this context. Furthermore, the support for this workflow on exascale systems will allow one more order of magnitude in complexity and accuracy for large eddy simulation of combustion processes.